Normally, my everyday life revolves around marketing, writing, and design—screwdrivers and soldering irons are not really part of it. But that's exactly what I tried out for two days: I was allowed to work in our production department and try my hand at it myself.

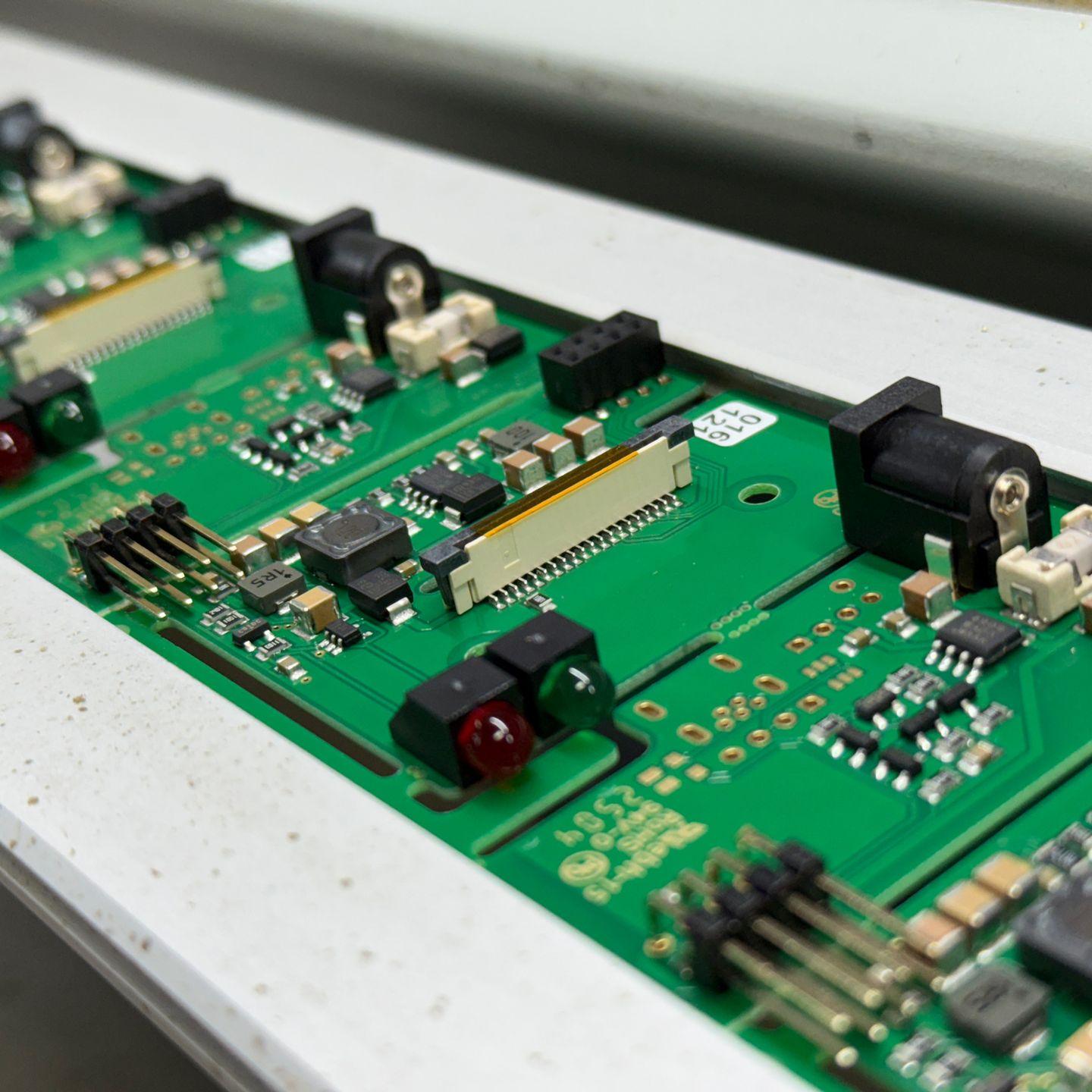

My plan was ambitious: to complete an entire order from start to finish on my own. That meant soldering, plugging, screwing, and assembling 60 charging brackets. It quickly became clear that precision and clear processes were essential.

A momentary lapse in concentration – and it happened: I had forgotten a cover and had to unscrew all the charging brackets again. 🙈 So much for “getting it done quickly.” But that's exactly what showed me how important structure and order are in production. My colleagues know exactly what they're doing, every process is well thought out – and when you try it yourself, you realize how much experience and care goes into it.

At the same time, though, it was a really good feeling to see the finished products in front of me at the end. To know: I actually put this together myself! Even though it wouldn't have been possible without the support of the team, of course—they got me through the day with patience, tips, and a good dose of humor.

My conclusion

It was incredibly fun to get involved in manual work away from my desk. What was even better was how helpful and patient my colleagues were in explaining everything to me. This not only gave me a better understanding of our products, but also provided me with a realistic insight into the everyday work of our production employees.

And one thing is certain: if things get tight, I'll be happy to sit down at a production table again anytime. Count me in!